When you're building a deck, it’s sometimes necessary to drill holes or cut notches in the framing for routing electrical cables or for installing gas piping. Because holes and notches can significantly weaken wood structural members, the IRC provides guidelines for making these onsite modifications, at least for sawn joists (see R502.8, 2012 IRC).

The rules aren’t quite so clear-cut when you need to modify a beam or a post, however. If you happen to be working with an engineered product, such as a treated glulam, you often can refer to the manufacturer’s instructions for notching or drilling guidance. In other cases, a basic understanding of the forces that act on horizontal and vertical framing members and of how wood framing resists these forces may allow you to safely make modifications using your common sense, or at least help you recognize when you should seek the judgment of a licensed engineer.

Bending and Shear

When a wood joist that's supported at both ends is loaded, it bends or deflects as it resists the force, pushing the fibers in the top edge of the joist together in compression and pulling the fibers in the bottom edge of the joist apart in tension. These stresses aren’t uniformly distributed throughout the joist; instead, they increase from zero at each end to their maximum at the center of the span. If you’ve ever experienced a binding saw blade when cutting the middle of a joist supported at both ends by sawhorses, you know that just the dead load of the lumber itself creates enough compression to pinch the blade in the kerf.

In addition to being subject to bending stress along their length, joists are also subject to shear stress. Shear acts parallel to the cross-section of the joist and resists the opposing forces of the load and the reaction (the upward force at the bearing point). Shear stresses increase uniformly from none at all at the center of the span out toward the bearing ends, where they are greatest. [Note that if a joist is also supported in the middle of its span, tension and compression are swapped near the middle support].

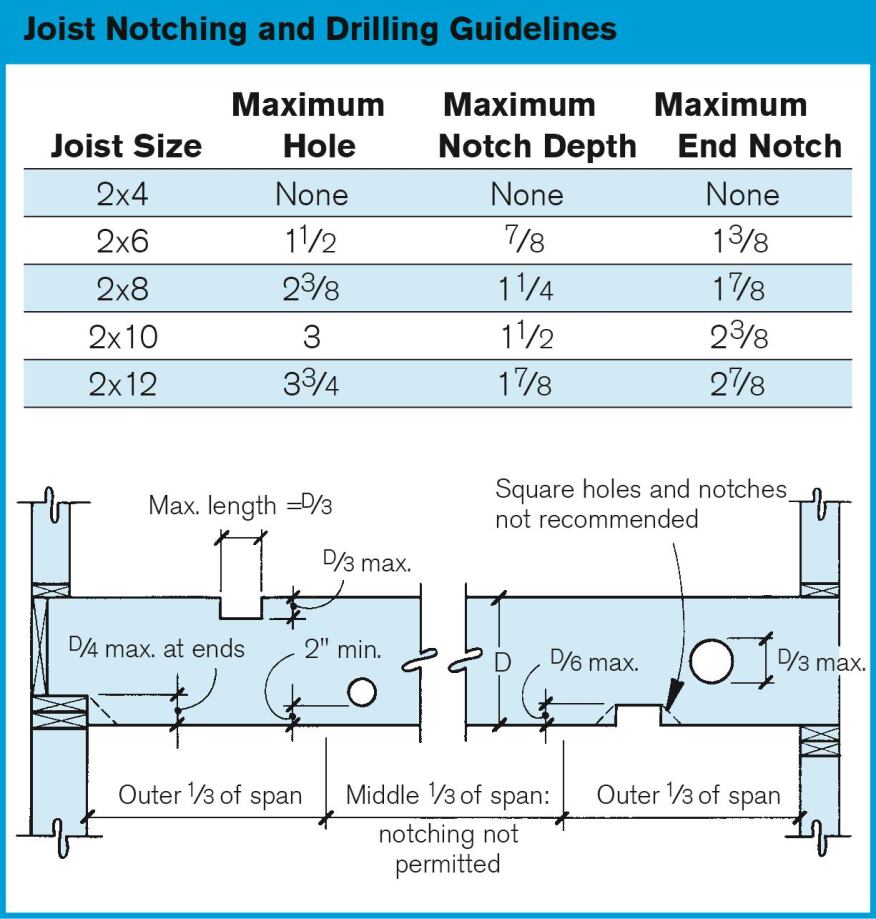

Notching. Notching involves the removal of material at the top and bottom of the joist, where compression and tension forces are working to resist bending (that is, deflection). Since bending forces increase toward the center of a beam and are greatest in the middle third of a span, the IRC prohibits any notches there (see "Joist Notching and Drilling Guidelines," above). If you’re considering laterally bracing the plane of a deck (a common wall-framing practice in the past, when they were sheathed with boards rather than structural panels, and still provided for in the IRC), this means you can’t let the bracing into the joists in the middle third of their span.

A joist can be notched at bearing locations at either the top or bottom without reducing its structural capability, as long as the notch doesn’t exceed one-fourth the depth of the joist. This means that a 2x10 can be notched at bearing to the height of a 2x8, yet still get span credit for being a 2x10. This allowance provides useful design flexibility; for example, when two different-sized joists bear at the same elevation and still must be flush on the top.

Notches can also be located anywhere along the top and bottom edges of the joist, as long as the notches are in the outer thirds of the span. These notches can’t be deeper than one-sixth the depth of the joist, nor longer than one-third the depth of the joist. In a 2x8 joist, for example, notches can be 1 1/4 inches deep, which should allow for recessed gas piping. Unlike electrical cable, gas pipe is rigid, and design restraints may preclude sliding the pipe through a series of drilled holes from outside the deck. Notches allow the pipe to be raised vertically into place.

When cutting notches in the bottom of a joist, try to make angled rather than vertical cuts, which will reduce the likelihood of splitting. Also, remember that with some pressure-treated material it may be a requirement of the AWPA standard M4, a required referenced standard of the IRC, for the exposed material in the cut to be field-treated. When not required, it's still good practice (see Decay Resistance and the Code, May 2014, PDB).

Drilling. There are two limitations to drilling holes in joists. To avoid reducing a joist’s bending resistance, no holes can be closer than 2 inches from the top or bottom edges of the joist. In addition, the diameter of a hole is limited to one-third the depth of the material. In a 2x8, for example, the maximum hole diameter is 2 3/8 inches (actual rather than nominal dimensions should be used to make these calculations).

Note that while rule #2 allows a 1 1/2-inch hole in a 2x6, this hole wouldn’t meet the 2-inch edge-clearance requirement of rule #1. Of course, in most deck applications, holes larger than what would be required for electrical wiring or gas piping are not common, so the maximum diameter usually isn't a problem. The edge distance, however, often is. For example, when joists are 12 inches on-center, ill-equipped carpenters who don't have a drill that will fit between the joists will end up drilling holes closer to the bottom edge than allowed. The IRC provides no alternative fix for holes less than 2 inches from the edge of a joist, and while an engineer might be able to come up with a solution, it will probably cost far more than a new right-angle drill would.

In the event that a single joist needs to be notched or drilled in more than one spot along its length, the distance between the holes or notches should be greater than twice the diameter of the largest opening. In the less-common event that engineered lumber approved for outdoor use is installed, refer to the manufacturer for drilling and notching limitations. Generally, I-joists' top and bottom chords cannot be notched to any degree, while holes in the center webs can be nearly chord to chord, certainly much larger than one-third the depth of the joist.

Beams

Provisions for deck beam spans and performance have only recently been added to the 2015 IRC, but so far there is no guidance for making any modifications to them. For one thing, loading assumptions for a joist are straightforward; for a beam, they’re not. Where a joist has just a span, size, and species to evaluate, a beam has those plus a variable load per linear foot that changes with every design. Identical beams in size, species, and span can have indefinite differences in how much load they carry, based on the span of the joists they support. This translates not only to variable forces within the beam, but also to variable concentrated loads at the bearing locations. Therefore, no safe assumptions can be made about beam modifications, and I know of no non-IRC source for guidance. The only options would be modifications so subtle that they would be hard to fret over (can anyone really believe a 1/2-inch-diameter hole through the center of a double 2x10 beam for electrical cable is going to cause any issues?) or modifications that would require the assistance of an engineer.

Posts

The IRC doesn’t provide modification allowances for notching and drilling support posts. It’s probably not worth worrying about minor holes, such as those used for low-voltage wiring. If the design calls for a large hole, such as for embedding the end of a 2-inch-diameter copper pipe as a decorative top rail in a custom guard, it might be wise to consult with your building inspector first. He may allow the hole if minimal material were to be removed to install the pipe, though he might also require the design of a structural engineer, depending on other loads supported by the post. Or he might suggest using a 6x6 rather than a 4x4 post.

Notching a post to recess a deck beam is usually not much of a concern, unless the post continues on to carry a roof or another deck above. Even then, provided the post is well connected to the deck against horizontal forces, and the notched portion bears tightly against the framing at the top and bottom, there's probably little concern. The vertical loads on a post require a large cross-section to resist the bending forces created in the post, and while a notch for a beam removes some of this cross-section, the beam also braces the post horizontally far better than any cross-sectional area would.

Again, there's no accepted engineering standard I can point to for post modifications, and a building authority would always reserve the right to request engineering. This is one of many good reasons for preparing clear building plans for permit review and addressing any possible concerns before the deck is built.